BLOG

Innovations in Medical Power Supply Design: How OEM Manufacturers Are Shaping the Future of Healthcare Devices

Table of contents

The demand for high-efficiency, reliable, and compliant medical power supplies is growing as the healthcare industry continues to evolve. From advanced imaging systems to life-saving ventilators, power supply technology plays a crucial role in ensuring patient safety, regulatory compliance, and device reliability.

OEM manufacturers specializing in medical-grade power supplies are integrating cutting-edge innovations to meet the needs of next-generation healthcare devices. These advancements include higher efficiency ratings, improved thermal management, intelligent power monitoring, and compliance with stringent medical safety standards.

This article explores the latest innovations in medical power supply design and highlights what OEMs should consider when selecting a trusted power supply manufacturing partner for healthcare applications.

Advancements in Medical Power Supply Efficiency

As medical devices become more sophisticated, power efficiency has become a top priority. Low-energy loss and high conversion efficiency ensure that devices operate with minimal heat generation, reducing the risk of overheating and power disruptions.

One of the major technological breakthroughs in power efficiency is the adoption of Gallium Nitride (GaN) and Silicon Carbide (SiC) semiconductors. These materials enable faster switching speeds and lower energy losses compared to traditional silicon-based components.

Modern power supplies are also designed to meet global energy efficiency standards, including DOE Level VI and EU CoC Tier 2, which regulate standby power consumption and conversion efficiency. Healthcare facilities that rely on continuous-use devices benefit from these advancements through lower operational costs and reduced environmental impact.

Key Features and Benefits

- Higher energy efficiency reduces heat output and extends product lifespan.

- Optimized power conversion ensures reliable and stable performance for medical applications.

- Compliance with global efficiency standards enhances device sustainability.

Best Practices

- Choose power supplies that meet the latest efficiency certification requirements.

- Work with a manufacturer that integrates next-generation semiconductor technology for improved performance.

- Ensure that the power supply minimizes power losses to support long-term reliability.

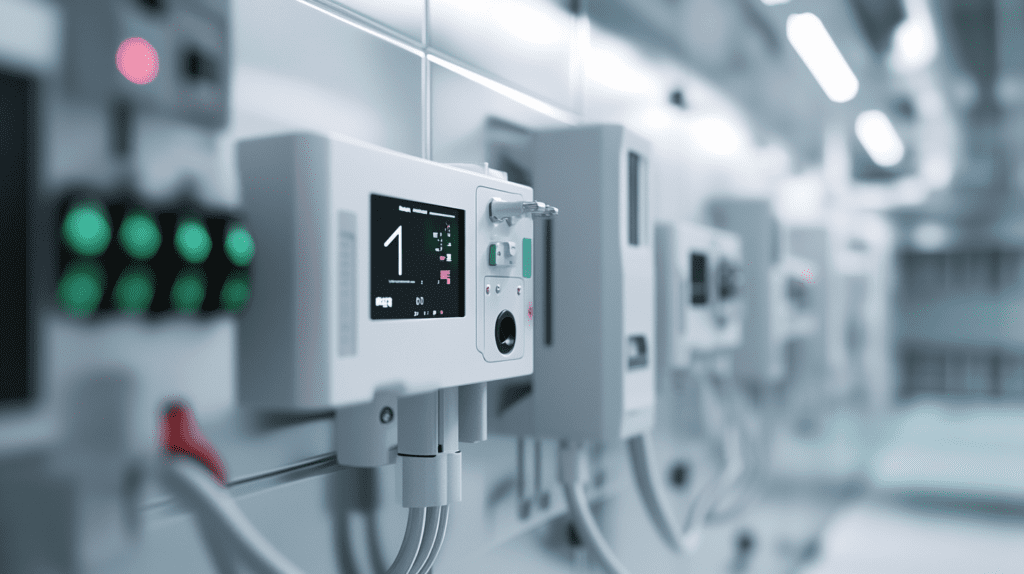

Intelligent Power Management for Medical Devices

Smart technology has revolutionized medical power supply designs, introducing intelligent power management features that enhance monitoring, diagnostics, and system safety. These features allow for real-time tracking of power usage, helping healthcare providers predict and prevent system failures.

Intelligent power management systems integrate microcontrollers and AI-driven analytics to optimize power distribution and voltage regulation. This ensures that critical medical devices, such as ventilators, dialysis machines, and imaging equipment, receive a stable and uninterrupted power supply.

Additionally, remote power monitoring capabilities allow technicians and medical staff to access real-time diagnostics, reducing downtime and enhancing maintenance efficiency. Some power supplies are equipped with self-correcting features that adjust power delivery based on real-time load requirements, ensuring stable operation.

Key Features and Benefits

- Smart diagnostics reduce device downtime and enhance operational efficiency.

- Adaptive power regulation prevents voltage fluctuations that could affect sensitive medical devices.

- Remote monitoring capabilities improve maintenance response times.

Best Practices

- Select power supplies with real-time power tracking and diagnostic tools.

- Ensure the manufacturer integrates intelligent power management software into the design.

- Look for power supplies with automated fault detection to minimize system failures.

Enhanced Safety and Compliance in Medical Power Supplies

Medical power supplies must comply with strict global safety standards to ensure patient safety and regulatory approval. One of the most critical standards is IEC 60601-1, which governs the electrical safety of medical equipment.

Power supplies for patient-connected devices must meet reinforced insulation, leakage current limitations, and EMI (electromagnetic interference) protection requirements. Many manufacturers now design power supplies with low-leakage and medical-grade isolation barriers to prevent electrical hazards in hospital environments.

Other important certifications include UL 60601, ISO 13485, and CE marking, which guarantee compliance with North American, European, and international medical regulations. Meeting these standards ensures that OEM medical power supplies can be used in sensitive healthcare environments without risk.

Key Features and Benefits

- IEC 60601 compliance ensures electrical safety in medical settings.

- Low leakage current designs reduce patient exposure to electrical hazards.

- Electromagnetic interference shielding prevents disruptions in sensitive medical equipment.

Best Practices

- Always confirm that the power supply meets industry safety certifications.

- Work with manufacturers that conduct stringent EMI and leakage current testing.

- Ensure compliance with regional and international regulatory standards to streamline approvals.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

Advanced Thermal Management Solutions for Medical Power Supplies

Heat dissipation is a critical factor in medical power supply design, as overheating can lead to device failures and reduced operational efficiency. To combat this, manufacturers are implementing advanced thermal management solutions that optimize cooling and heat dissipation.

Newer power supplies integrate active and passive cooling techniques, including heat sinks, liquid cooling systems, and phase-change thermal materials. These improvements increase energy efficiency and allow for smaller, more compact power supply designs.

Additionally, smart thermal monitoring provides real-time temperature tracking, allowing devices to self-regulate cooling mechanisms and prevent overheating.

Key Features and Benefits

- Optimized cooling extends power supply lifespan and maintains stable operation.

- Smart thermal management prevents overheating and system shutdowns.

- Compact designs allow for space-saving integration in modern medical devices.

Best Practices

- Choose power supplies that feature integrated heat management technologies.

- Work with manufacturers that offer thermal modeling and real-world stress testing.

- Ensure that the power supply is designed to operate in high-temperature hospital environments.

Customization and Scalability for Future Medical Applications

As medical devices continue to evolve, OEM manufacturers require scalable and customizable power solutions. Customization ensures that power supplies are tailored to specific medical applications, allowing for optimal efficiency, safety, and integration.

Scalable power supply designs support upgrades and next-generation technology integration without requiring a complete redesign. Features like programmable voltage outputs, modular designs, and adaptive power delivery help OEMs future-proof their medical devices.

Phihong specializes in custom medical power supply solutions, offering flexible configurations that adapt to emerging healthcare needs.

Key Features and Benefits

- Customizable voltage and power outputs for unique medical applications.

- Modular designs support future upgrades and technology advancements.

- Scalable production ensures availability as device demands evolve.

Best Practices

- Work with manufacturers that provide flexible power supply customization options.

- Ensure scalability to support long-term product lifecycle management.

- Choose power supplies with programmable configurations to adapt to future industry changes.

Next-Generation Battery Backup and Uninterruptible Power Solutions

Reliability is paramount in medical power supply design, particularly for critical care devices, surgical equipment, and life-sustaining technologies. Power failures or fluctuations can pose serious risks, making battery backup and uninterruptible power solutions (UPS) essential for medical OEMs.

Modern medical power supplies integrate advanced battery backup features that ensure continuous operation during power outages or voltage fluctuations. These systems utilize high-efficiency lithium-ion (Li-ion) and supercapacitor technology to provide instant switchover capabilities without interruptions. Additionally, some UPS solutions are designed for portable medical devices, allowing continuous operation even during patient transport.

Another innovation in medical-grade UPS systems is adaptive load balancing, where power supplies intelligently distribute available energy based on device priority. This feature ensures that critical systems—such as ventilators and defibrillators—maintain full functionality, even in power-restricted scenarios.

Key Features and Benefits

- Seamless power transitions during electrical failures prevent device shutdowns in critical moments.

- Lithium-ion and supercapacitor-based battery backups ensure higher efficiency and extended life cycles.

- Adaptive load balancing prioritizes power for life-sustaining medical devices.

Best Practices

- Choose a power supply manufacturer that offers integrated UPS functionality for medical devices.

- Work with manufacturers that test load balancing efficiency to optimize power use during outages.

- Ensure compliance with IEC 60601-1-2 standards for electromagnetic compatibility in emergency scenarios.

With next-generation UPS and backup power solutions, medical OEMs can guarantee operational reliability, improving patient safety and device resilience.

The Role of Cybersecurity in Medical Power Supply Design

As medical devices become increasingly connected, cybersecurity threats in power supply systems have become a growing concern. Smart medical power solutions, which integrate IoT-based monitoring and remote diagnostics, must be designed with robust security features to prevent cyber vulnerabilities.

Power supply hacking incidents have raised alarms in the healthcare sector, with threats including remote tampering, unauthorized shutdowns, and data breaches. To combat these risks, manufacturers are implementing secure firmware, encrypted power communication protocols, and multi-layer authentication for remote access.

Modern medical-grade power supplies also integrate tamper-proof hardware components, ensuring that malicious software cannot override safety mechanisms. Additionally, fail-safe power delivery systems can automatically switch to protected energy reserves if suspicious activity is detected.

Key Features and Benefits

- Secure power firmware updates prevent system vulnerabilities.

- Encryption and authentication protocols protect against cyber attacks on medical infrastructure.

- Fail-safe power isolation features ensure critical devices remain operational under security threats.

Best Practices

- Choose power supplies that feature secure boot and encrypted firmware updates.

- Work with manufacturers that integrate intrusion detection and power anomaly monitoring.

- Ensure compliance with HIPAA, FDA cybersecurity guidelines, and IEC 62443 for medical cybersecurity standards.

With cybersecurity-focused power supply designs, medical OEMs can protect patient safety, prevent cyber threats, and ensure compliance with evolving security regulations.

Phihong: A Trusted OEM Partner for Medical Power Supply Innovation

The future of medical power supply design is shaped by technological advancements, efficiency improvements, and compliance-driven manufacturing. OEMs looking for a trusted manufacturing partner need a supplier that offers custom solutions, global compliance, and long-term scalability.

Phihong has been at the forefront of medical power supply innovation, offering high-efficiency, safety-certified, and smart power solutions tailored for healthcare applications. With manufacturing capabilities in Vietnam, Phihong provides OEMs with a reliable and flexible supply chain, ensuring on-time production and regulatory compliance.

Why Choose Phihong for Medical Power Supply Solutions?

- Certified medical power supplies – Phihong’s products meet IEC 60601-1, UL, CE, and ISO 13485 standards, ensuring safety and reliability.

- Custom power solutions for medical devices – Offering programmable power adapters, high-efficiency AC-DC converters, and backup power systems tailored to specific healthcare needs.

- Smart power technologies – Integrated real-time monitoring, cybersecurity protection, and fail-safe battery backups for continuous power management.

- Global manufacturing with supply chain stability – Vietnam production facilities ensure a reliable and scalable supply chain, minimizing risks of disruptions or component shortages.

- Lifecycle support and product longevity – Phihong offers firmware updates, technical support, and power supply lifecycle management to meet the evolving needs of the medical industry.

As OEM manufacturers search for trusted power supply partners, Phihong’s expertise in medical power design ensures compliance, innovation, and scalability. Whether your business needs high-efficiency AC-DC adapters, programmable medical chargers, or advanced UPS solutions, Phihong delivers cutting-edge power technology built for the future of healthcare devices.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

Why are medical power supplies different from standard commercial power supplies?

Medical power supplies are designed with stricter safety, reliability, and compliance requirements than standard commercial power supplies. They must meet IEC 60601-1 medical safety standards, ensuring low leakage current, reinforced insulation, and electromagnetic interference (EMI) protection. These features are critical for patient-connected devices, as any electrical fluctuations or faults could pose serious health risks.

In addition to safety, medical-grade power supplies incorporate fail-safe mechanisms, backup power redundancy, and intelligent power management to maintain continuous operation during power interruptions. Many healthcare devices, such as MRI scanners, patient monitors, and life-support systems, require uninterrupted power, making battery backup and UPS integration essential.

Finally, medical power supplies must comply with global regulatory approvals, including UL 60601, CE Marking, FDA cybersecurity guidelines, and ISO 13485 for quality assurance.

How do smart power supplies benefit medical devices?

Smart power supplies integrate real-time monitoring, adaptive voltage control, and predictive diagnostics, allowing healthcare facilities to optimize energy use, prevent failures, and extend device lifespans.

By incorporating IoT-based power management, medical OEMs gain remote access to diagnostics, power usage analytics, and automated fault detection. These features reduce maintenance downtime and improve overall system reliability.

Smart power supplies also support secure firmware updates, ensuring that devices remain cybersecure and compliant with evolving regulations.

What factors should OEMs consider when selecting a medical power supply manufacturer?

Choosing a reliable medical power supply partner requires evaluating:

- Regulatory compliance – Power supplies should be IEC 60601-1 certified for medical applications.

- Customization capabilities – OEMs should work with manufacturers that offer programmable voltage, smart monitoring, and power redundancy options.

- Supply chain stability – Choose a supplier with manufacturing redundancy in Vietnam to ensure continuous production.

OEMs should prioritize certified, customizable, and future-proof power solutions when selecting a manufacturer.

How does thermal management impact medical power supply performance?

Effective thermal management prevents device overheating, power loss, and system failures. Medical power supplies integrate active cooling systems (fans, liquid cooling, and phase-change materials) and passive heat dissipation (heat sinks, airflow optimization) to regulate temperatures and maintain efficiency.

Advanced thermal sensors and smart cooling algorithms ensure that power supplies self-regulate cooling based on real-time load conditions, preventing performance degradation.

Why should OEMs choose Phihong for their medical power supply needs?

Phihong offers custom-engineered, safety-certified, and highly efficient power supplies tailored for medical devices. With expertise in intelligent power management, cybersecurity protection, and compliance-driven designs, Phihong provides OEMs with a trusted partner for next-generation medical power solutions.

Partner with Phihong today and future-proof your medical power supply technology.