BLOG

Best Power Supply Manufacturers for OEMs: How to Choose the Right Partner for Performance and Compliance

Table of contents

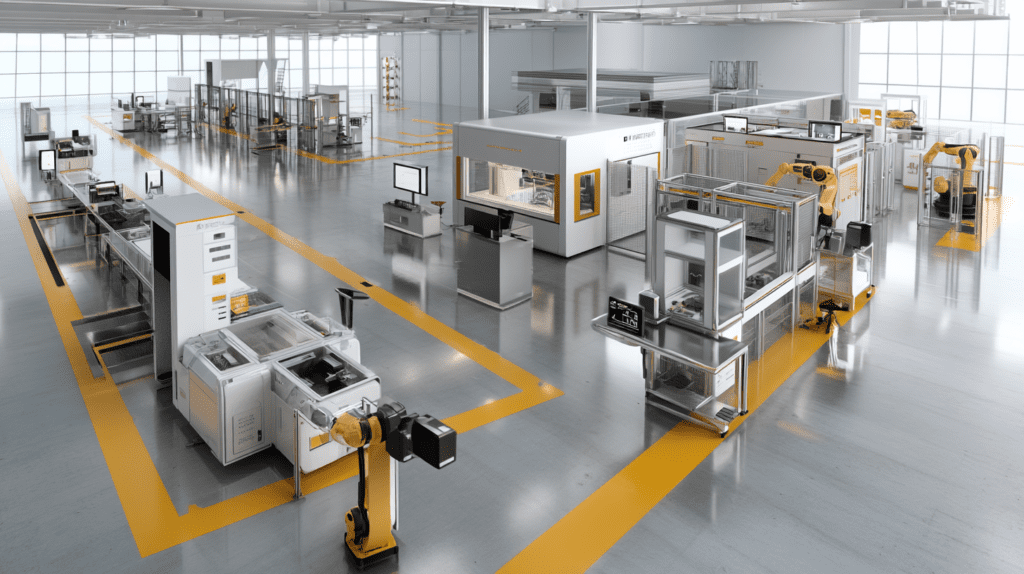

Choosing the right power supply manufacturer can make or break the success of an OEM’s product line. From industrial automation and medical equipment to telecom and consumer electronics, each application requires a power solution that is efficient, reliable, and fully compliant with safety regulations. Yet with dozens of global manufacturers claiming to offer the best products, how do OEMs identify a partner that meets their performance needs while ensuring long-term supply chain success?

This guide breaks down what OEMs should look for when evaluating power supply manufacturers, highlighting key capabilities, industry standards, and best practices that separate top-tier partners from basic component vendors.

What Sets the Best Power Supply Manufacturers Apart

The best power supply manufacturers aren’t just component producers—they’re long-term partners that contribute to product success, operational efficiency, and compliance. A manufacturer that understands the complexities of OEM manufacturing provides much more than just off-the-shelf units.

Key Qualities of a Top-Tier Power Supply Manufacturer

Engineering and Technical Expertise

- Offers in-house design, custom power engineering, and thermal management optimization.

- Understands the electrical demands of the OEM’s target industry.

Compliance with Global Standards

- Products meet UL, IEC, ISO, CE, and Energy Star certifications.

- Maintains up-to-date testing and documentation for regulatory approval across markets.

Flexible Manufacturing Capabilities

- Supports low-volume prototyping and high-volume production.

- Provides scalable manufacturing in multiple regions for global supply chain stability.

Proven Track Record

- Demonstrates experience across multiple industries, including industrial, medical, and telecom.

- Offers case studies, reliability data, and customer testimonials.

Best Practices for OEMs Identifying High-Quality Manufacturers

- Evaluate the manufacturer’s history of compliance with evolving global standards.

- Request product samples and third-party test reports.

- Look for a manufacturer that offers customization, documentation support, and long-term lifecycle management.

By partnering with a manufacturer that offers technical expertise, global compliance, and flexible production, OEMs can ensure their power systems are built to perform—today and in the future.

Why Compliance and Certifications Matter in Power Supply Manufacturing

For OEMs, power supply compliance isn’t optional—it’s a requirement for global market access, product safety, and long-term reliability. Manufacturers that fail to meet international standards can put OEMs at risk of failed inspections, product recalls, or regulatory fines.

Common Power Supply Certifications and What They Mean

UL (Underwriters Laboratories)

- Required for North American market access.

- Verifies electrical safety, including insulation, temperature ratings, and flammability.

IEC an ISO ertifications

- IEC 62368-1: Covers IT and industrial safety.

- ISO 9001: Ensures quality management and manufacturing consistency.

CE Marking and RoHS Compliance

- Required for sales in the European Union.

- Ensures products are free from hazardous materials and meet environmental safety guidelines.

DOE Level VI and Energy Star

- U.S. Department of Energy energy efficiency standards for external power supplies.

- Helps OEMs market products as eco-friendly and energy-saving.

Best Practices for Ensuring Compliance

- Always confirm that the manufacturer holds valid certifications for your target markets.

- Ask for updated certification documentation and audit histories.

- Choose manufacturers that proactively update designs to meet upcoming regulatory changes.

Working with a power supply manufacturer that prioritizes compliance ensures smoother product development, faster time-to-market, and reduced regulatory risk for OEMs.

How Customization Sets Top Power Supply Manufacturers Apart

While off-the-shelf power supplies might meet basic technical requirements, custom power solutions offer significant advantages in efficiency, integration, and long-term reliability. The best power supply manufacturers are those who can tailor solutions to meet the unique voltage, thermal, form factor, and compliance needs of their OEM partners.

Benefits of Custom Power Supply Solutions

Tailored Electrical Performance

- Optimized for specific load profiles, peak current demands, and voltage regulation.

- Reduces inefficiencies and enhances system-level performance.

Thermal and Mechanical Integration

- Custom footprints, cable lengths, or enclosures improve thermal airflow and design flexibility.

- Eliminates excess heat buildup that can compromise device longevity.

Support for Specialized Environments

- Ruggedized designs for industrial or military use.

- Low-noise and low-leakage power solutions for medical applications.

Built-in Safety and Compliance Features

- Pre-certified designs that meet UL, IEC, or MIL-STD requirements.

- Integration of surge protection, PFC, or EMI filtering tailored to application-specific risks.

Best Practices for OEMs Sourcing Custom Power Solutions

- Look for manufacturers that provide in-house engineering and prototyping services.

- Request examples of past custom solutions in similar industries.

- Ensure the manufacturer supports thermal modeling, compliance testing, and mechanical integration.

By choosing a power supply partner that excels in customization, OEMs can differentiate their products, improve reliability, and streamline product development timelines.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

How Supply Chain Stability Impacts OEM Power Supply Selection

Supply chain reliability is a critical factor when evaluating power supply manufacturers. Inconsistent delivery timelines, raw material shortages, or regional disruptions can delay product launches and erode customer trust. The best power supply partners have built-in strategies for supply continuity, sourcing flexibility, and inventory control.

Key Traits of a Supply Chain-Ready Manufacturer

- Multiple manufacturing locations (e.g., Vietnam and other regions) to mitigate geographic risk

- Long-term relationships with component suppliers to ensure part availability

- Flexible lead times for low- and high-volume production cycles

- Just-in-time inventory management and transparent logistics tracking

Best Practices for OEMs Prioritizing Supply Chain Stability

- Ask about the manufacturer’s regional production footprint and sourcing strategy

- Ensure vendor has risk mitigation plans for geopolitical or supply disruptions

- Confirm capacity for both prototyping and volume ramp-ups

Choosing a manufacturer with a strong, flexible supply chain allows OEMs to meet demand, scale efficiently, and navigate disruptions without compromising product delivery.

What Role Does Innovation Play in Power Supply Partnerships?

In a rapidly changing technology landscape, OEMs benefit from manufacturers who are actively investing in next-generation power innovations, including GaN and SiC semiconductors, AI-integrated power management, and compact high-wattage designs. Innovation impacts not just product performance but also lifecycle value.

Signs of an Innovative Power Supply Manufacturer

- Offers engineering support for high-efficiency and programmable power designs

- Invests in R&D for advanced materials and thermal management

- Supports integration with AI, IoT, and real-time monitoring systems

- Participates in industry certifications and compliance forums to stay ahead of regulatory shifts

Best Practices for OEMs Seeking Innovative Partners

- Review the manufacturer’s product roadmap and R&D investment

- Ask for examples of industry-first designs or patented technologies

- Evaluate the ability to support new standards and power architectures

Partnering with an innovation-driven manufacturer helps OEMs future-proof their products, adapt to market shifts, and deliver better-performing solutions to end users.

Why Lifecycle Support and Technical Service Matter to OEMs

A great power supply manufacturer provides more than just parts—they offer ongoing support, documentation, and product lifecycle services that extend beyond the initial delivery. This is especially important in medical, telecom, or industrial applications where uptime and compliance require continuous reliability.

What OEMs Should Expect from Lifecycle Support

- Technical documentation including CAD, thermal models, and regulatory reports

- Firmware updates and performance enhancements throughout the product lifecycle

- Return merchandise authorization (RMA) programs and issue resolution

- Ongoing engineering support for modifications, replacements, or design refreshes

Best Practices for OEMs Requiring Long-Term Support

- Choose a vendor with a dedicated support team and defined escalation process

- Confirm availability of long-term spare parts or extended lifecycle guarantees

- Ask about historical product support timelines and customer satisfaction ratings

Reliable lifecycle support ensures OEMs can maintain compliance, extend product longevity, and respond quickly to any technical or customer challenges in the field.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ