BLOG

How to Choose the Best OEM Power Supply Manufacturer for Medical Devices: Key Factors for Compliance and Performance

Table of contents

Medical devices require highly reliable, safety-compliant, and efficient power solutions to ensure consistent performance and patient safety. Whether it’s AC-DC adapters, DC-DC converters, PoE (Power over Ethernet) devices, or UPS (Uninterruptible Power Supplies), selecting the right OEM power supply manufacturer is critical for medical equipment manufacturers.

Choosing a trusted partner involves evaluating regulatory compliance, customization capabilities, energy efficiency, and long-term product reliability. This guide will cover the essential factors that medical OEMs should consider when selecting a power supply manufacturer, ensuring compliance with IEC 60601-1, ISO 13485, and other industry standards.

Regulatory Compliance for Medical Power Supplies

Medical power supplies must adhere to strict international safety standards to ensure patient protection and reliable operation. The IEC 60601-1 standard is the gold standard for electrical safety in medical devices, regulating factors such as leakage current, insulation requirements, and electromagnetic interference (EMI) shielding.

Other essential compliance certifications include:

| Certification | Purpose | Application |

| IEC 60601-1 | Safety & Performance | Patient-connected medical devices |

| UL 60601-1 | Electrical Safety | North American medical device approval |

| ISO 13485 | Quality Management | Medical device production standards |

| FCC & CE Marking | EMI & Compliance | Global electronic device safety |

| RoHS & WEEE | Environmental Safety | Restriction of hazardous substances |

Key Considerations:

- Ensure that power supplies meet low leakage current requirements to prevent patient exposure to electrical faults.

- Work with a manufacturer that conducts electromagnetic compatibility (EMC) testing to minimize interference with critical medical systems.

- Verify that the power supply complies with global medical regulations to ensure seamless international distribution.

Best Practices:

- Select fully certified power supplies that meet regional and global medical safety requirements.

- Work with a manufacturer that regularly updates compliance protocols in line with evolving healthcare regulations.

- Request third-party compliance validation reports to confirm certified manufacturing practices.

A regulatory-compliant power supply manufacturer ensures that medical devices meet industry safety standards, reducing compliance risks and regulatory delays.

Key Power Supply Solutions for Medical Devices

OEM manufacturers require a range of power supply solutions tailored for specific medical applications. Each device type plays a crucial role in ensuring stable power delivery, energy efficiency, and operational reliability.

AC-DC Medical Power Adapters

- Used in patient monitors, infusion pumps, ventilators, and imaging devices.

- Designed for energy efficiency and compact size while maintaining reinforced isolation and low leakage current.

- Must meet DOE Level VI and Energy Star certifications for low standby power consumption.

DC-DC Converters for Medical Electronics

- Essential for battery-powered medical devices, such as portable imaging systems, handheld diagnostic tools, and implantable medical electronics.

- Converts power from battery packs or low-voltage DC sources to the required operational voltage.

- Optimized for high-efficiency, low-noise operation in sensitive healthcare environments.

PoE Power Solutions for Medical Facilities

- PoE (Power over Ethernet) technology is used for telemedicine equipment, security cameras, nurse call systems, and remote monitoring devices.

- Enables data transmission and power delivery over a single Ethernet cable, simplifying installation and reducing wiring costs.

- Meets IEC 60601-1-2 (EMC) requirements, ensuring that networked medical devices do not interfere with critical hospital equipment.

Uninterruptible Power Supplies (UPS) for Medical Applications

- UPS systems provide emergency power backup for surgical instruments, life-support systems, and MRI scanners.

- Prevents power interruptions in hospitals and medical facilities.

- Advanced UPS solutions integrate smart monitoring and predictive maintenance for long-term reliability.

Best Practices

- Work with a manufacturer that offers customizable AC-DC and DC-DC power solutions tailored to medical device specifications.

- Ensure PoE power supplies comply with medical EMC and isolation standards for safe hospital integration.

- Choose UPS backup solutions to eliminate downtime risks for critical medical equipment.

By selecting a manufacturer that offers a complete range of medical power solutions, OEMs can ensure seamless device integration and operational stability.

Energy Efficiency & Thermal Management for Medical Power Supplies

Energy efficiency is a top priority in medical power supply design. Reducing energy consumption and heat output ensures reliable performance and longer device lifespans.

Medical power supplies must meet DOE Level VI and EU CoC Tier 2 standards, ensuring minimum power loss and standby energy efficiency. Innovations such as GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductors allow for higher power densities and reduced switching losses.

Thermal Management Strategies

- Passive cooling techniques – Includes heat sinks and improved PCB layouts to dissipate heat efficiently.

- Active cooling systems – Uses forced-air cooling and liquid cooling for high-power medical applications.

- Smart thermal monitoring – Power supplies with built-in temperature sensors adjust cooling dynamically, preventing overheating.

Best Practices

- Select power supplies with high-efficiency conversion rates (above 90%) to reduce energy waste and heat generation.

- Ensure power supplies are designed with integrated heat management solutions to extend device lifespan.

- Work with a manufacturer that performs rigorous thermal stress testing to prevent overheating failures.

By prioritizing energy efficiency and thermal regulation, medical OEMs can enhance device longevity and safety while maintaining low power consumption.

Selecting the Right Medical-Grade PoE Power Solutions

Power over Ethernet (PoE) technology has gained traction in the medical industry due to its ability to deliver both power and data over a single cable. This simplifies hospital infrastructure, improves equipment efficiency, and enhances patient care through wireless monitoring systems, security cameras, and nurse call stations.

Medical PoE power supplies must meet stringent safety and electromagnetic compatibility (EMC) standards to avoid interference with critical hospital equipment such as MRI machines, ventilators, and life-support systems.

Key Considerations

- Compliance with IEC 60601-1-2 EMC regulations to prevent electromagnetic interference in hospital environments.

- High-power PoE injectors and switches capable of delivering stable power to telemedicine and patient monitoring devices.

- Low-noise power solutions to ensure seamless operation in sensitive healthcare environments.

Best Practices

- Choose PoE power supplies that support networked medical devices while maintaining strict safety standards.

- Work with manufacturers that test and certify their PoE solutions to ensure they meet hospital and clinical requirements.

- Opt for PoE power solutions that feature redundant power protection, safeguarding mission-critical hospital systems.

With PoE-enabled medical power solutions, healthcare facilities can achieve a more efficient, scalable, and integrated infrastructure, improving patient outcomes and hospital automation.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

Custom Power Supply Solutions for Portable and Wearable Medical Devices

The rise of portable and wearable medical devices has increased demand for custom power supply solutions that offer lightweight designs, long battery life, and energy efficiency. Devices such as portable ECG monitors, insulin pumps, and wearable diagnostic sensors require compact, low-power solutions while maintaining regulatory compliance.

Innovations in wireless charging and high-efficiency DC-DC converters have enabled better power management for these devices, allowing for extended use between charges while ensuring precise power control.

Key Considerations

- Low-power consumption and high energy density batteries to extend device runtime.

- Wireless charging capabilities for seamless patient usability.

- Compliance with ISO 13485 and IEC 60601-1 to ensure safe operation in clinical and home healthcare settings.

Best Practices

- Work with a manufacturer that provides customized power solutions for portable medical devices.

- Ensure high-efficiency DC-DC power conversion for optimized battery life and reduced heat generation.

- Choose power supplies with intelligent power monitoring to enhance device reliability and safety.

As wearable and portable medical devices continue to grow, custom power solutions will be critical in ensuring their long-term performance and usability.

Importance of Redundant Power and Fail-Safe Mechanisms in Medical Equipment

Medical devices must operate without power disruptions, particularly in life-supporting applications such as ICU ventilators, defibrillators, and surgical instruments. Redundant power systems ensure that in the event of a power failure, backup energy sources activate instantly to maintain continuous operation.

Uninterruptible power supplies (UPS) and dual-power input power supplies are common in hospitals and emergency healthcare facilities, offering instant power switchover and battery backup capabilities.

Key Considerations

- UPS-integrated power supplies for critical life-saving equipment.

- Automatic voltage regulation (AVR) and fail-safe redundancy to protect against power fluctuations.

- Multi-layer protection including overvoltage, short-circuit, and power surge resistance.

Best Practices

- Implement redundant power solutions for critical medical applications that cannot tolerate downtime.

- Ensure power supplies meet hospital-grade UPS and emergency power specifications.

- Choose manufacturers with proven reliability in medical-grade fail-safe power designs.

By incorporating redundant power solutions and fail-safe mechanisms, healthcare providers can protect patients from risks associated with power failures and maintain uninterrupted medical services.

Phihong: A Trusted OEM Power Supply Partner for Medical Devices

Selecting a trusted OEM power supply manufacturer is critical for ensuring device compliance, efficiency, and reliability. Phihong offers custom-engineered power solutions designed to meet the unique challenges of medical device manufacturers.

Why Choose Phihong?

- IEC 60601-1 certified medical power supplies – Fully compliant with medical safety regulations and global approvals.

- Custom AC-DC and DC-DC power solutions – Engineered for medical imaging, patient monitoring, and life-support systems.

- Advanced PoE and smart power technologies – Supporting networked healthcare devices, telemedicine, and hospital automation.

- High-efficiency designs with thermal management – Energy-saving power supplies that minimize heat generation and enhance reliability.

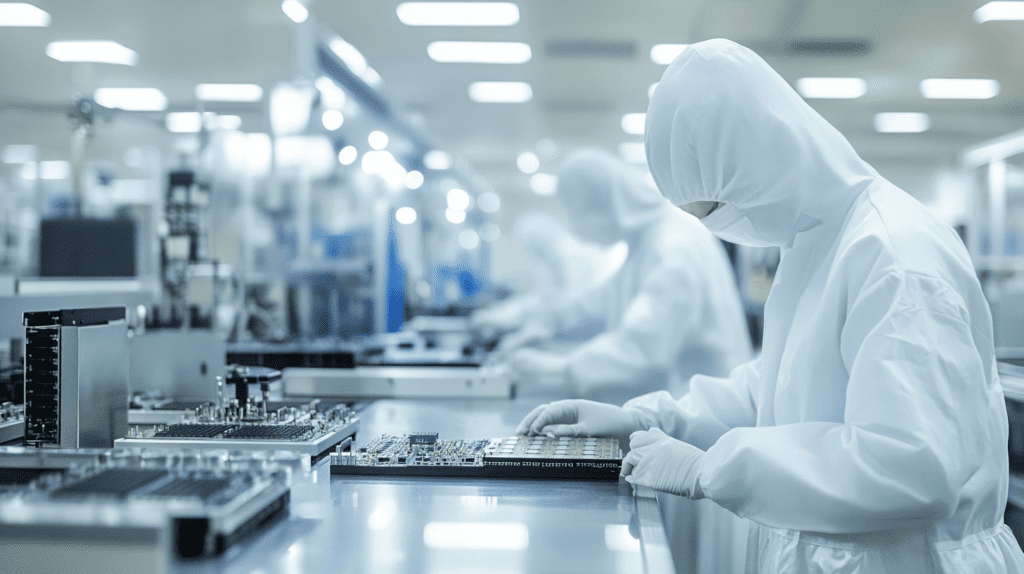

- Global manufacturing in Vietnam – Stable supply chain with scalable production capacity.

As medical OEMs seek reliable, high-efficiency power solutions, Phihong remains a trusted global partner for next-generation healthcare devices.

Explore Phihong’s medical power supply solutions today and future-proof your healthcare technology.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What are the key factors to consider when choosing an OEM power supply manufacturer for medical devices?

Selecting an OEM power supply manufacturer for medical devices requires careful evaluation of several critical factors to ensure compliance, reliability, and performance. The first consideration is regulatory compliance, as medical power supplies must meet IEC 60601-1 safety standards, which govern electrical safety, leakage current limits, and electromagnetic compatibility (EMC) to prevent device interference. Compliance with ISO 13485 also ensures that the manufacturer follows strict quality management systems for medical device production.

Another crucial factor is customization capabilities. Medical power supplies often have unique voltage, power efficiency, and thermal requirements that off-the-shelf solutions cannot meet. Working with a manufacturer that provides custom AC-DC, DC-DC, and PoE solutions ensures optimal integration into specialized healthcare devices.

Supply chain reliability is equally important. Manufacturers with facilities in multiple locations, such as Vietnam, offer OEMs greater production stability, lower shipping costs, and reduced lead times.

Additionally, smart power features such as real-time monitoring, battery backup, and fail-safe mechanisms improve device reliability, especially for life-support and emergency medical systems.

OEMs should also assess the manufacturer’s long-term support, technical expertise, and post-sales service, ensuring they provide firmware updates, lifecycle management, and rapid troubleshooting when needed.

By choosing a manufacturer that excels in compliance, scalability, innovation, and product longevity, OEMs can confidently integrate safe and efficient power supplies into their medical applications.

Why do medical power supplies need to comply with IEC 60601-1 and other global standards?

Medical power supplies must comply with IEC 60601-1 to meet the highest safety and performance standards for healthcare applications. Unlike standard power supplies, medical-grade power solutions are used in patient-connected devices, surgical instruments, and life-support systems, where electrical failures can pose serious risks.

IEC 60601-1 ensures that medical power supplies meet strict insulation, grounding, and leakage current requirements, preventing electric shock, equipment malfunctions, and patient harm. Leakage current must be kept below 100μA for direct patient-connected equipment, significantly lower than industrial or consumer-grade power supplies.

Beyond IEC 60601-1, manufacturers must also comply with:

- UL 60601 (North America): Verifies safety compliance for medical electrical equipment.

- ISO 13485 (Global): Regulates quality management in medical device manufacturing.

- FCC and CE (EMC Compliance): Ensures electromagnetic compatibility so power supplies do not interfere with other medical devices.

- RoHS and WEEE (Environmental Standards): Restrict the use of hazardous materials like lead, mercury, and cadmium.

Complying with these standards allows OEMs to sell their devices globally while ensuring safe, reliable, and interference-free power supply integration.

Choosing a certified power supply manufacturer eliminates compliance risks, speeds up regulatory approval, and enhances patient safety, making IEC 60601-1 compliance non-negotiable for medical power applications.

What role does energy efficiency play in medical power supply design?

Energy efficiency in medical power supplies directly impacts device performance, reliability, and long-term operational costs. High-efficiency power supplies reduce wasted energy, generate less heat, and improve power delivery stability, which is crucial for sensitive medical equipment such as patient monitors, ventilators, and imaging systems.

The introduction of GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductors has significantly improved efficiency levels, allowing medical devices to operate at higher power densities with minimal energy loss. These innovations contribute to reduced power consumption, particularly in battery-powered medical devices, ensuring longer runtimes and faster charging cycles.

Modern medical power supplies must also meet DOE Level VI and EU CoC Tier 2 efficiency regulations, ensuring compliance with international energy standards. These regulations set minimum efficiency levels and standby power limits, helping healthcare facilities reduce electricity costs and environmental impact.

Thermal management plays a critical role in energy-efficient power design. Advanced heat dissipation techniques, such as heat sinks, liquid cooling, and smart temperature sensors, help regulate operating temperatures while maintaining optimal efficiency levels.

For OEMs, choosing a manufacturer that prioritizes energy efficiency ensures that medical power supplies remain compliant, cost-effective, and reliable in critical healthcare settings.

How does PoE (Power over Ethernet) enhance medical equipment power delivery?

Power over Ethernet (PoE) technology is becoming a game-changer in hospital infrastructure, allowing data and power transmission over a single Ethernet cable. This reduces the need for separate power sources, simplifying installation, enhancing flexibility, and improving reliability for networked medical equipment.

PoE is commonly used in:

- Remote patient monitoring devices – Allows continuous patient data transmission without requiring a dedicated power outlet.

- Security and nurse call systems – Supports 24/7 surveillance cameras and emergency response systems within hospitals.

- Telemedicine stations – Ensures stable power delivery for digital healthcare kiosks and virtual consultation hubs.

- Smart hospital lighting and IoT sensors – Reduces hospital energy costs by powering intelligent lighting systems and smart building automation.

PoE-enabled power supplies must comply with medical safety standards to ensure that networked hospital devices do not interfere with sensitive medical equipment. Compliance with IEC 60601-1-2 (EMC regulations) ensures that PoE-powered devices operate within strict electromagnetic interference limits.

Advanced PoE solutions now support up to 90W (PoE++), enabling high-power applications such as digital imaging systems and interactive medical displays.

OEMs looking to integrate PoE power solutions into medical devices should partner with manufacturers specializing in custom medical-grade PoE power supply designs to ensure compliance, stability, and performance.

Why should medical OEMs choose Phihong as their power supply manufacturer?

Phihong is a leading OEM power supply manufacturer that specializes in customized power solutions for medical devices. With a strong focus on regulatory compliance, efficiency, and innovation, Phihong is the ideal partner for healthcare manufacturers requiring certified, scalable, and high-performance power supplies.

Key Reasons to Choose Phihong

- Certified medical power supplies – All Phihong medical-grade power solutions comply with IEC 60601-1, ISO 13485, and UL safety standards, ensuring global regulatory approval.

- Custom power solutions for medical devices – Offering AC-DC adapters, DC-DC converters, PoE solutions, and redundant power backup systems, Phihong provides flexible designs tailored to OEM requirements.

- High-efficiency and smart power designs – Incorporating energy-efficient GaN-based power solutions, thermal management innovations, and fail-safe redundancy features, Phihong ensures optimal device operation.

- Reliable global manufacturing – With production facilities in Vietnam, Phihong provides a stable, scalable supply chain that minimizes lead times and production risks.

- Industry-leading technical support and lifecycle management – Phihong offers comprehensive technical assistance, firmware updates, and product lifecycle support, ensuring long-term reliability for medical OEMs.

For OEMs seeking a trusted medical power supply manufacturer, Phihong delivers cutting-edge power solutions backed by decades of experience, certified production, and a commitment to innovation.

Partner with Phihong today and enhance your medical power supply capabilities for next-generation healthcare devices.