BLOG

OEM Battery Charger Manufacturer: Where to Source Custom Power Charging Solutions for Your Product Line

Table of contents

For any OEM developing battery-powered products—whether it’s handheld medical equipment, industrial robotics, electric scooters, or smart home devices—the battery charger is more than just an accessory. It’s a critical part of the user experience and product performance. That’s why choosing the right OEM battery charger manufacturer is essential.

A well-designed charger helps ensure battery longevity, user safety, compliance with global regulations, and compatibility across your product ecosystem. But with so many off-the-shelf and white-label options available, how do you find a manufacturer that can provide a truly custom, scalable solution?

In this guide, we’ll walk you through what makes a reliable OEM battery charger partner, where to source custom solutions, and what to consider as your product line grows.

Why Custom Battery Chargers Are Essential for OEM Product Success

While generic chargers might seem convenient, they rarely align with the specific voltage, current, and charging profile your product needs. A custom OEM charger is designed to deliver optimized charging performance while meeting safety and efficiency standards.While it may be tempting to go with a generic charger for its convenience, it’s important to remember that these off-the-shelf solutions are rarely tailored to meet the unique power requirements of your specific product. Every product has its own distinct voltage, current, and charging profile needs, and a generic charger simply cannot accommodate these individual specifications. This mismatch can lead to suboptimal charging performance, potential safety hazards, and decreased product lifespan.

A custom OEM charger, on the other hand, is designed from the ground up to deliver the precise charging performance your product requires. It takes into account the specific voltage and current demands of your product’s battery and internal circuitry, ensuring that the charging process is both safe and efficient. Moreover, a custom OEM charger can be tailored to meet specific charging profiles, such as fast charging or trickle charging, further optimizing the charging experience for the end-user.

By investing in a custom OEM charger, you are not only ensuring optimal charging performance for your product but also demonstrating a commitment to quality and safety. This can enhance your brand reputation and give you a competitive edge in the marketplace. Additionally, a custom OEM charger can be designed to meet specific regulatory and compliance standards, ensuring that your product is safe and legal for use in its intended markets.

Key Benefits of Custom Charging Solutions

- Tailored voltage/current output to match your battery chemistry (Li-ion, LiFePO4, NiMH, etc.)

- Built-in smart features like temperature sensing, trickle charging, or overcharge protection

- Compatibility with global input voltages for international sales

- Enhanced mechanical fit, branding, and connector design

Best Practices for OEMs

- Share battery specifications and use cases with your manufacturer early

- Consider fast-charging needs and regulatory compliance from the beginning

- Design the charger as a core part of the product—not an afterthought

With a custom power charging solution, you get a safer, more efficient, and more brand-aligned product experience.

What to Look for in an OEM Battery Charger Manufacturer

Sourcing the right manufacturer is about more than comparing price tags. A trusted partner will help you develop a charger that fits your technical requirements, supports your production goals, and meets compliance regulations for every region you sell in.When sourcing a manufacturer, it’s crucial to look beyond just the cost. A reliable partner will collaborate with you to design a charger that aligns with your technical specifications, supports your production targets, and adheres to the compliance standards of all the regions where you market your product. This comprehensive approach ensures that your charger is not only cost-effective but also technically sound, efficient to produce, and legally compliant in all your target markets.

Must-Have Qualities in a Manufacturer

- Experience with your battery type and target industry

- In-house electrical, thermal, and mechanical engineering

- Capabilities for UL, CE, FCC, RoHS, and IEC certification

- Ability to support both low-volume and mass production

- Proven quality assurance and supply chain reliability

Best Practices for Evaluation

- Ask about custom firmware, connector options, and IP-rated enclosures

- Request examples of similar product builds or industries served

- Ensure documentation and test reports are available for regulatory submissions

The right partner will be involved from concept to post-launch support—helping you deliver reliable power, faster development, and peace of mind.

How Scalable Charger Solutions Support Your Product Line Growth

As your business grows, so do your charging needs. Whether you’re adding SKUs, entering new markets, or upgrading to newer battery technologies, you need a power supply manufacturer that can scale with you—without requiring a full redesign every time.As your business expands and evolves, your power supply requirements will inevitably change as well. This growth could manifest in various ways, such as the introduction of new products and SKUs to your lineup, the expansion into new geographical markets or customer segments, or the adoption of newer and more advanced battery technologies.

In any of these scenarios, it’s crucial to partner with a power supply manufacturer that possesses the agility and scalability to adapt to your changing needs seamlessly. The ideal partner will be able to accommodate these changes without necessitating a complete and costly redesign of your power solution every time your business requirements shift. This adaptability will not only save you time and money but also ensure that your power supply infrastructure remains aligned with your business goals and objectives.

How Scalable Charging Design Helps OEMs

- Shared components across multiple product families to reduce costs

- Modular designs that support future battery chemistries or voltage ranges

- Global certifications for international compliance and distribution

- Firmware-upgradable chargers that adapt to new features or safety protocols

Best Practices for Planning Ahead

- Choose a manufacturer that supports design reusability across models

- Work with partners who track regulatory trends and offer pre-certified options

- Plan for multi-market compliance, from North America to the EU and beyond

Scalable battery charger solutions let you grow faster, launch smoother, and minimize engineering rework as your lineup expands.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

Certifications and Safety Considerations for OEM Battery Chargers

OEM battery chargers must meet strict safety and compliance standards to ensure proper function, avoid battery degradation, and protect end users. Choosing a manufacturer familiar with these regulations helps you get to market faster—and with fewer risks.Original Equipment Manufacturer (OEM) battery chargers are essential components for a wide range of products, and they must adhere to stringent safety and compliance standards. These standards ensure that the chargers function correctly, preventing issues like battery degradation and potential harm to end users.

Selecting a manufacturer with a proven track record of compliance with these regulations is crucial for several reasons. Firstly, it significantly streamlines the process of bringing your product to market. By partnering with an experienced manufacturer, you can avoid costly delays and setbacks that may arise from non-compliance issues. Secondly, it minimizes the risks associated with product safety and liability. A manufacturer familiar with the relevant regulations can help you ensure that your product meets all the necessary requirements, reducing the likelihood of legal or financial repercussions.

In addition to safety and compliance, other factors to consider when choosing an OEM battery charger manufacturer include their experience and expertise in the specific battery technology your product requires, their ability to meet your production volume and timeline requirements, and their pricing and terms. By carefully evaluating these factors, you can find a manufacturer that can provide you with high-quality, reliable, and compliant battery chargers that meet the needs of your product and your customers.

Common Compliance Standards for Battery Chargers

- UL 1310 / UL 62368-1: U.S. safety standards for low-voltage power and consumer/ICT equipment

- CE and RoHS: Required for European market entry, confirming safety and material restrictions

- FCC: Verifies EMI/EMC compatibility for the U.S.

- IEC 62133 / IEC 60335-1: International standards for rechargeable battery systems and household appliances

- DOE Level VI / Energy Star: Efficiency benchmarks for external power supplies

Best Practices for OEMs

- Share your target regions and certifications during early design

- Ask for full documentation and third-party test results

- Confirm the charger includes overvoltage, short-circuit, and temperature protection

A properly certified charging solution safeguards your product and brand—while keeping compliance costs and time-to-market under control.

Why OEMs Trust Phihong for Custom Battery Charger Manufacturing

Phihong has decades of experience designing custom power solutions—including smart battery chargers—for OEMs in medical, industrial, mobility, and consumer markets. Our products are known for reliability, safety, and global compliance, backed by responsive technical support.

What Phihong Offers OEMs

- Custom AC-DC and DC-DC chargers tailored to your battery chemistry and voltage

- Compliance support for UL, CE, FCC, DOE, and industry-specific certifications

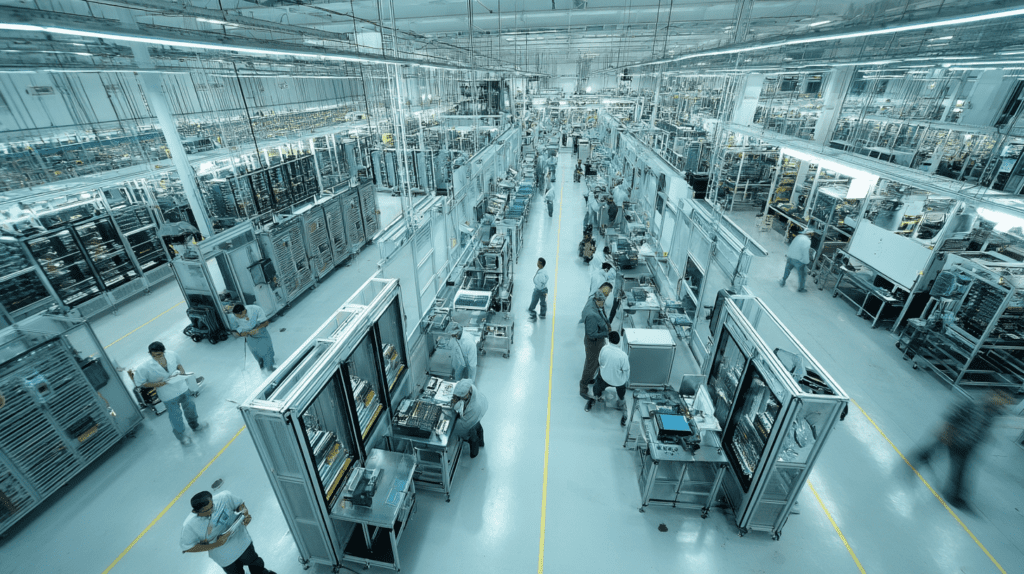

- Global production, including facilities in Vietnam, with scalable delivery capabilities

- Support for rugged, medical-grade, and waterproof charger designs

- Engineering-led development with firmware and safety features built in

Whether you’re launching a new device or upgrading your product line, Phihong delivers smart, efficient, and safe charging solutions that support your success long after launch.

Getting Started with the Right Battery Charger Manufacturer

Starting with the right power partner saves time, prevents product recalls, and ensures your chargers perform consistently across your full lineup. A collaborative manufacturer will walk you through design, testing, and regulatory approval—then help you scale with confidence.

First Steps for OEMs

- Define your power specs, charging profile, and enclosure needs

- Share your battery chemistry, intended use, and region of distribution

- Ask about sample timelines, certification strategy, and lifecycle support

What to Expect from a Great Partner

- Transparent communication and regular engineering updates

- Flexibility to customize or modify designs for future products

- Ongoing technical assistance and post-launch support

When you choose a manufacturer who understands both charging technology and your long-term vision, you’re not just buying hardware—you’re building a foundation for dependable power across your product line.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What makes a battery charger “OEM-grade”?

An OEM-grade battery charger is designed specifically for integration into a branded product, rather than as a universal or aftermarket solution. These chargers are engineered with the OEM’s battery specifications, safety standards, and performance requirements in mind.

Unlike off-the-shelf models, OEM-grade chargers are often custom-built or modified to meet very specific voltage and current outputs. They may also be optimized for a particular battery chemistry—like lithium-ion, lithium-iron-phosphate (LiFePO4), nickel-metal hydride, or lead-acid.

OEM chargers often include features such as short-circuit protection, overcharge and thermal protection, and intelligent charging curves based on battery behavior. They’re also developed with the enclosure, connector, and environmental conditions of the OEM product in mind.

Most importantly, OEM-grade battery chargers are certified to meet all relevant safety and compliance standards required for regional or global sale. That includes UL, CE, FCC, RoHS, and energy efficiency standards.

Working with a custom charger manufacturer ensures that your product is safer, performs better, and maintains a consistent brand experience across your product line.

Can I use a standard charger for my OEM product?

In many cases, standard chargers may not deliver the performance, safety, or compatibility needed for OEM products. While they’re useful for initial prototyping or testing, standard power supplies often fall short in commercial applications—especially when long-term reliability, regulatory compliance, or product integration is involved.

Generic chargers may not align with your battery’s charging profile, resulting in longer charge times, battery degradation, or performance inconsistencies. They might also lack critical safety features like thermal cutoff, short-circuit protection, or voltage regulation—putting both the product and end-user at risk.

Standard models are also rarely optimized for space, weight, or ruggedization—common needs in OEM applications. They may not be certified for your target regions, and documentation is often limited or unavailable.

A better approach is working with a charger manufacturer who can tailor solutions to your battery type, usage scenario, and compliance targets. This ensures proper integration, protects your investment, and delivers a better user experience.

What certifications are required for OEM battery chargers?

The certifications your battery charger needs will depend on your target market, product category, and industry. However, here are the most common and important ones:

- UL / cULus: U.S. and Canadian electrical safety standards for power supplies

- CE (LVD + EMC): European safety and electromagnetic compatibility certification

- FCC (Part 15): Ensures minimal interference with radio and communication devices

- RoHS / REACH: Environmental regulations limiting hazardous substances in electronics

- DOE Level VI / Energy Star: Efficiency standards for external power supplies

- IEC 62133 / IEC 60335 / IEC 60601-1: Required for batteries and chargers in consumer, industrial, and medical markets respectively

Your charger manufacturer should be experienced with these standards and able to provide all necessary documentation, test reports, and markings for each region. Pre-certification and in-house compliance support will also accelerate your approval process and prevent delays.

What are the benefits of working with a custom charger manufacturer?

Working with a custom charger manufacturer gives you more control over your product’s performance, safety, branding, and certification pathway. Instead of compromising with an off-the-shelf charger, you get a tailored solution that supports your battery chemistry, charge cycle goals, and form factor requirements.

Custom chargers can be built to meet specific environmental conditions—such as waterproofing, vibration tolerance, or industrial enclosures. They also allow for connector customization, cable length adjustments, mounting options, and thermal management features.

Another major benefit is certification. A custom partner will design your charger with UL, CE, FCC, and RoHS compliance in mind—saving you time and resources during product approvals.

If you need future-proofing, a good manufacturer will support firmware updates, design revisions, and component continuity. That’s especially important for medical, industrial, or long-lifecycle devices.

In short, custom charging isn’t just about making your product work—it’s about making it better, safer, and more scalable.

Why do OEMs choose Phihong as their battery charger manufacturer?

OEMs choose Phihong because we combine power supply expertise with a deep understanding of battery technology, product compliance, and long-term manufacturing strategy. Our chargers are used in everything from medical carts and handheld scanners to industrial robots, e-mobility, and telecom gear.

Phihong supports full customization—from voltage and current profiles to connector types, thermal specs, and enclosures. Whether you’re working with Li-ion, NiMH, or lead-acid batteries, we’ll help you design a safe, reliable, and efficient charging solution.

Our products meet UL, CE, FCC, DOE, and other global certifications, and we provide full documentation and traceability for your compliance needs. With global production capabilities, including facilities in Vietnam, we offer scalable manufacturing with cost-effective lead times and strong QA processes.

OEMs appreciate our engineering-first approach, lifecycle support, and ability to deliver both innovation and dependability—every step of the way.