BLOG

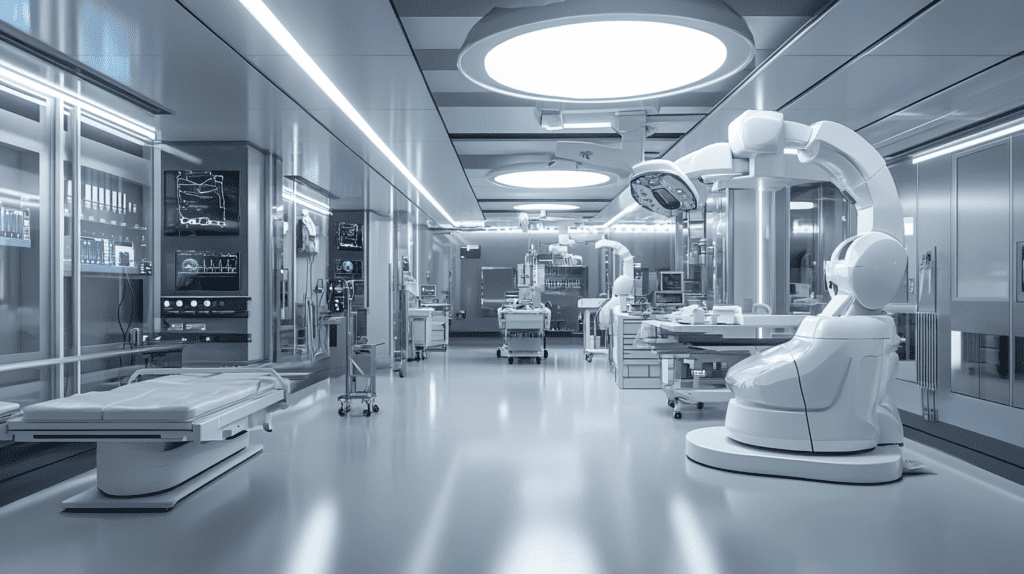

Robotics Power Supply Manufacturing: The Future of Wireless and Contactless Power Solutions in Robotics

Table of contents

Wireless and contactless power solutions are transforming robotics power supply manufacturing, offering new ways to improve energy efficiency, reduce downtime, and eliminate physical connectors. As industrial automation, AI-driven robots, and autonomous systems continue to evolve, traditional wired power systems face limitations, such as cable wear, connection failures, and restricted mobility.

With advancements in wireless charging, inductive power transfer, and resonant energy transmission, robotics OEMs are exploring wireless and contactless power solutions to enhance reliability, scalability, and design flexibility. This guide examines the future of wireless power in robotics, including key technologies, benefits, and challenges that manufacturers must address to successfully integrate next-generation power systems.

How Wireless and Contactless Power Solutions Are Changing Robotics Power Supply Manufacturing

The demand for seamless power solutions in robotics is driving the adoption of wireless and contactless power transfer (CPT). Unlike traditional power systems that rely on cables and connectors, these advanced solutions enable power delivery without direct physical connections, reducing maintenance costs, increasing mobility, and improving safety in various robotic applications.

Key Wireless and Contactless Power Technologies in Robotics

Inductive Power Transfer (IPT)

- Uses electromagnetic induction to wirelessly transfer power between coils.

- Commonly used in autonomous mobile robots (AMRs) and automated guided vehicles (AGVs).

Resonant Wireless Power Transfer

- Uses magnetic resonance coupling for longer-distance power transmission.

- Ideal for medical robotics, logistics automation, and AI-driven robotic systems.

Radio Frequency (RF) Energy Harvesting

- Converts radio waves into usable power, enabling low-power sensor and IoT device charging.

- Applied in wireless robotic sensors, smart factories, and industrial IoT networks.

Capacitive Wireless Power Transfer

- Uses electric fields to transfer power across insulating barriers.

- Suitable for medical robots and cleanroom environments where physical contact must be minimized.

Best Practices for OEMs Implementing Wireless and Contactless Power Solutions

Evaluate application requirements to determine the best wireless power transfer method.

Test wireless power efficiency and range to optimize charging speeds and reliability.

Work with power supply manufacturers that specialize in robotics wireless power integration.

By adopting wireless and contactless power solutions, robotics OEMs can eliminate cable constraints, enhance automation flexibility, and future-proof robotic systems.

The Benefits of Wireless Power Solutions for Robotics

As robotics applications expand into more demanding environments, traditional wired power connections present challenges related to wear, mobility limitations, and system failures. Wireless and contactless power technologies offer significant advantages in efficiency, durability, and operational flexibility.

Key Advantages of Wireless Power in Robotics

Eliminates Cable and Connector Wear

- No physical contact points, reducing mechanical failures and maintenance costs.

- Ideal for continuous-motion robotics in industrial and logistics applications.

Enhances Mobility and Flexibility

- Wireless charging allows autonomous robots to recharge without docking stations.

- Eliminates tethered power limitations, improving navigation and workspace efficiency.

Reduces Risk of Electrical Failures and Downtime

- No exposed wires means less risk of disconnections, cable fraying, or power failures.

- Improves safety in hazardous environments, such as factories and medical settings.

Optimizes Power Management for Battery-Powered Robots

- Wireless power delivery reduces downtime for battery-powered robotic systems.

- Supports real-time power adjustments based on robotic workload and energy demands.

Best Practices for OEMs Integrating Wireless Power Technologies

Select wireless power systems that align with robotic energy needs and environmental conditions.

Ensure interoperability between wireless power sources and robotic charging infrastructure.

Work with power supply manufacturers that offer customized wireless power solutions for robotics.

By leveraging wireless and contactless power solutions, robotics OEMs can increase system reliability, enhance automation capabilities, and reduce maintenance costs.

Challenges of Wireless and Contactless Power in Robotics

While wireless power solutions offer exciting advancements, robotics OEMs must address several technical and operational challenges before full-scale adoption. These challenges include efficiency limitations, energy transfer distances, and regulatory compliance for industrial and medical robotics.

Key Challenges in Robotics Wireless Power Integration

Energy Transfer Efficiency

- Wireless charging typically has lower efficiency compared to direct wired connections.

- Power loss during transmission affects battery charging speeds and energy usage.

Limited Power Transfer Distance

- Inductive charging requires close-range coil alignment, restricting charging flexibility.

- Long-range wireless power transfer still faces technical and regulatory hurdles.

Electromagnetic Interference (EMI) Concerns

- Wireless power systems can generate EMI, which may disrupt sensors and communication in robotics.

- EMI shielding and regulatory compliance are essential for sensitive applications like medical robotics.

Scalability for High-Power Robotics Applications

- Many wireless power technologies are still limited in delivering high-wattage power.

- Large-scale industrial robots require high-power wireless charging solutions that can handle increased energy demands.

Best Practices for Overcoming Wireless Power Challenges in Robotics

Choose high-efficiency wireless power transfer systems to reduce energy loss.

Design robotic power architectures with integrated EMI shielding and noise reduction.

Work with power supply manufacturers specializing in large-scale wireless power integration.

By addressing these challenges, robotics OEMs can successfully integrate wireless power solutions, improving automation efficiency, reducing downtime, and future-proofing robotic systems.

CLIENT'S QUOTE

"Phihong’s PoE solutions have made a huge difference for us! Our network runs more efficiently, and we’ve seen real cost savings. We couldn’t be happier!"

How Robotics OEMs Can Implement Wireless and Contactless Power Solutions

For robotics OEMs, transitioning to wireless and contactless power solutions requires careful planning, testing, and integration into existing robotic systems. Unlike traditional wired power setups, wireless power solutions must be optimized for efficiency, safety, and seamless energy transfer in real-world applications.

Key Steps for OEMs Adopting Wireless Power

Assess Power Requirements and Application Needs

- Identify energy consumption patterns and charging frequency to determine suitable wireless power technologies.

- Evaluate charging distances, power output, and efficiency ratings for different robotic applications.

Develop Compatible Charging Infrastructure

- Design wireless charging stations and power hubs to support autonomous robots and mobile systems.

- Ensure interoperability between wireless power sources and robotic energy management systems.

Optimize Wireless Power for Efficiency and Reliability

- Select high-efficiency inductive or resonant power transfer technologies for optimal performance.

- Implement real-time power monitoring systems to track energy transfer and prevent losses.

Test Power Delivery in Real-World Environments

- Conduct field testing in industrial, medical, and logistics environments to measure charging efficiency and range.

- Optimize placement of wireless power transmitters and receivers to maximize energy transfer.

Best Practices for Robotics OEMs Transitioning to Wireless Power

Ensure compliance with industry standards for wireless power efficiency and safety.

Work with power supply manufacturers specializing in wireless charging solutions.

Develop scalable charging infrastructure to accommodate future robotics advancements.

By following these steps, robotics OEMs can successfully integrate wireless power solutions, improving automation flexibility, operational uptime, and energy efficiency.

The Future of Wireless Power in Robotics Manufacturing

As wireless power technology continues to evolve, robotics manufacturers are exploring new innovations that improve energy transfer efficiency, extend power transmission distances, and enable fully autonomous charging solutions. The future of robotics power supply manufacturing will be defined by increased automation, seamless energy integration, and enhanced sustainability.

Emerging Trends in Wireless Power for Robotics

Long-Range Wireless Power Transmission

- Advancements in resonant and RF-based power transfer are enabling longer-range energy transmission.

- Future industrial robots may operate without docking stations, continuously charging while in motion.

AI-Optimized Power Distribution

- AI-driven energy management systems analyze real-time robotic power usage and dynamically adjust wireless power distribution.

- Smart power allocation ensures higher efficiency and lower energy waste in automation systems.

Integration with Smart Factory and IoT Systems

- Wireless power is being integrated into Industry 4.0 and smart manufacturing facilities, allowing robots to receive continuous, real-time energy management.

- IoT connectivity improves wireless charging coordination and predictive energy allocation.

Sustainable and Eco-Friendly Wireless Power Solutions

- Robotics manufacturers are exploring solar-powered wireless charging stations to reduce reliance on traditional energy sources.

- Future robots will utilize self-sustaining power ecosystems, reducing downtime and improving energy efficiency.

Best Practices for OEMs Preparing for the Future of Wireless Power

Stay informed on new wireless power technologies and industry advancements.

Work with manufacturers that develop scalable wireless power infrastructure.

Integrate AI-powered energy management systems for optimized wireless charging.

As robotics move toward full automation and energy independence, wireless power technology will play a key role in improving efficiency, sustainability, and performance in robotic systems.

Why Phihong is a Leader in Wireless Power Solutions for Robotics

Phihong is a global leader in power supply manufacturing, specializing in wireless and contactless power solutions for robotics OEMs. With a strong focus on high-efficiency energy transfer, intelligent power management, and scalable automation solutions, Phihong helps robotics manufacturers integrate the latest wireless power technologies into their systems.

What Makes Phihong a Trusted Wireless Power Supply Manufacturer?

Advanced Wireless Power Technologies

- Phihong develops high-efficiency inductive and resonant wireless power solutions for robotic applications.

- Designed for fast, reliable energy transfer with minimal power loss and maximum efficiency.

Custom Wireless Power Solutions for Robotics OEMs

- Offers tailored wireless charging solutions for autonomous mobile robots (AMRs), industrial automation, and medical robotics.

- Supports modular and scalable charging infrastructure to accommodate future robotics advancements.

Industry-Leading Safety and Compliance Standards

- Wireless power solutions meet UL, IEC, and ISO certifications, ensuring regulatory compliance.

- Low electromagnetic interference (EMI) designs support safe operation in industrial and medical environments.

Global Manufacturing and Scalable Production Capabilities

- Phihong provides flexible production options, from low-volume prototyping to large-scale wireless power integration.

- Ensures supply chain stability and consistent product availability for high-demand robotics applications.

Best Practices for OEMs Partnering with Phihong for Wireless Power Solutions

Collaborate with Phihong’s engineering team to develop custom wireless charging systems.

Ensure compliance with wireless power safety and efficiency standards.

Leverage Phihong’s global production network for scalable wireless power supply solutions.

By partnering with Phihong, robotics OEMs gain access to cutting-edge wireless power technologies, advanced energy transfer solutions, and future-proof charging infrastructure, making Phihong an ideal partner for next-generation robotics power supply needs.

Contact Our Team Today!

Our dedicated sales team and international partners are prepared to support you with your latest projects and initiatives globally.

Explore More with Phihong USA

As we conclude our exploration of PoE technology, it’s evident how these innovations are streamlining power and data integration across various industries. Phihong USA stands at the forefront of this technological advancement, offering a diverse range of power solutions designed to meet the evolving needs of modern industries.

Phihong USA’s extensive product lineup includes:

- Power over Ethernet (PoE) Solutions: Delivering reliable power and data transmission over a single cable, ideal for simplifying network installations and reducing costs.

- AC/DC Adapters and Power Supplies: From compact adapters to industrial-grade power supplies, Phihong provides solutions that ensure efficiency and reliability in various applications.

- Battery Chargers: Customizable chargers for lithium-ion and lead-acid batteries, supporting a wide range of power requirements for mobility and industrial applications.

- Medical Power Supplies: Specialized power solutions designed to meet the stringent requirements of the healthcare industry, ensuring safety and reliability.

Phihong USA is committed to innovation and excellence, continually developing products that meet the highest standards of performance and reliability. Their global reach and dedication to customer support make them a trusted partner in powering the future.

Here are some useful links to explore Phihong USA’s offerings further and bring in new potential clients:

Visit Phihong USA to discover how their advanced power solutions can support your business needs. Whether you’re looking to upgrade your network, or find reliable power supplies, Phihong USA has you covered.

By choosing Phihong USA, you’re partnering with a leader in power technology, ensuring your operations run smoothly and efficiently with top-tier power solutions. Contact Us today!

FAQ

What are the key benefits of wireless power solutions in robotics?

Wireless power solutions offer robotics manufacturers several advantages over traditional wired power connections. One of the biggest benefits is eliminating cable wear and tear. In high-motion robotics applications, power cables are often subject to mechanical stress, leading to frayed wires and frequent maintenance issues. Wireless power solutions remove this failure point, ensuring longer-lasting and more reliable power delivery.

Another key advantage is increased mobility and design flexibility. Robots that rely on wired power connections are restricted in movement, limiting their efficiency in automation. Wireless power allows greater range of motion, uninterrupted workflows, and self-charging capabilities, which are particularly useful in autonomous mobile robots (AMRs), warehouse automation, and AI-powered robotics.

Wireless power also improves safety and operational efficiency. In industrial and medical robotics, exposed wires and physical connections pose safety risks, including electrical shorts and tripping hazards. Contactless power transfer eliminates these risks, reducing system downtime and creating safer working environments.

In terms of efficiency, wireless power solutions are becoming more optimized for energy conversion, reducing power losses compared to older inductive charging methods. Emerging technologies such as resonant power transfer and AI-driven energy management are improving overall efficiency and ensuring faster, seamless power delivery for modern robotic systems.

For OEMs looking to enhance mobility, increase safety, and reduce maintenance costs, wireless power is a transformative solution that aligns with the next generation of robotics automation.

What are the main challenges of wireless power adoption in robotics?

While wireless power offers many advantages, it also presents several challenges that OEMs must address before full-scale adoption. One of the biggest concerns is energy transfer efficiency. Wireless charging is typically less efficient than wired connections, meaning some energy is lost during transmission. This can lead to longer charging times and higher power consumption if not properly optimized.

Another challenge is power transfer distance. Many wireless power systems require close-range alignment between the transmitter and receiver, making it difficult to integrate for robots that operate in dynamic environments. Long-range wireless charging is still in its early stages and requires further technological advancements to match the efficiency of traditional wired solutions.

Electromagnetic interference (EMI) is another factor. Wireless power transmission can generate electromagnetic fields that interfere with nearby electronic devices and sensors, which is especially critical in medical robotics and industrial automation. OEMs must ensure that their wireless power solutions meet strict EMI compliance standards to prevent disruptions.

Additionally, scalability and infrastructure development are challenges. Many facilities and warehouses are still designed for wired power connections, meaning a shift to wireless charging requires investment in new charging stations, power hubs, and infrastructure upgrades.

Despite these challenges, advancements in AI-driven power management, optimized energy transmission, and regulatory compliance improvements are making wireless power a viable and attractive option for robotics manufacturers.

How does contactless power transfer work for industrial and autonomous robots?

Contactless power transfer (CPT) is revolutionizing the way industrial and autonomous robots receive energy by eliminating physical charging ports and enabling seamless power delivery. CPT works by transmitting electricity wirelessly through inductive, resonant, or capacitive coupling, ensuring robots can charge while in motion or stationed near a power source.

In inductive power transfer, power is transmitted between coils in the transmitter and receiver through an electromagnetic field. This technology is widely used in automated guided vehicles (AGVs), warehouse robots, and logistics automation, where robots follow predetermined paths and charge wirelessly at designated points.

Resonant power transfer allows for longer-distance energy transmission by tuning both the transmitter and receiver to the same frequency. This method is ideal for medical robots and AI-driven industrial automation, where precise power delivery is required without physical connections.

Capacitive power transfer uses electric fields to transmit energy, making it suitable for cleanroom environments and medical applications where direct contact must be avoided.

The biggest advantage of contactless power transfer is continuous energy replenishment, which reduces downtime and increases productivity. Instead of returning to charging docks, robots can receive energy on the move, making workflows more efficient and scalable.

With continuous advancements in AI-driven energy monitoring and real-time power allocation, CPT is expected to become a standard in industrial robotics, autonomous mobility, and smart factory automation.

Is wireless power safe for medical and industrial robotics applications?

Yes, wireless power is designed to be safe for both medical and industrial robotics applications, but OEMs must ensure compliance with strict safety standards to avoid risks such as electromagnetic interference, energy loss, and overheating.

In medical robotics, power supplies must comply with IEC 60601-1, which governs electrical safety in patient-connected devices. Wireless power solutions used in robotic-assisted surgery, patient monitoring, and AI-powered diagnostics must have low electromagnetic emissions to prevent interference with medical imaging and communication equipment.

For industrial robotics, wireless power solutions must meet UL and IEC standards for efficiency and electrical insulation to protect workers from electric shock hazards. EMI shielding is also crucial, especially in factories where multiple wireless energy sources operate simultaneously.

Additionally, smart energy management systems are integrated into modern wireless power solutions to prevent overcharging, regulate voltage fluctuations, and optimize energy transfer efficiency. AI-driven power regulation further enhances safety by adjusting energy output based on real-time robotic demands.

Wireless power technology is also improving in thermal safety. Early inductive charging systems generated excess heat, but next-generation resonant power transfer and smart cooling technologies reduce heat buildup, ensuring safe operation in high-performance robotic systems.

When properly designed and tested for compliance, wireless power is a safe and effective solution for robotics applications, ensuring seamless power delivery while maintaining strict industry safety requirements.

Why should robotics OEMs choose Phihong for their wireless power supply needs?

Phihong is a pioneer in wireless power supply manufacturing, offering high-efficiency, contactless power solutions for robotics OEMs. With extensive experience in industrial automation, medical robotics, and AI-driven robotic systems, Phihong develops wireless charging technology that enhances mobility, reliability, and efficiency.

Phihong’s custom-engineered wireless power solutions provide robotics OEMs with tailored charging systems, ensuring seamless integration into autonomous robots, AGVs, warehouse automation, and medical robotics.

Key advantages of working with Phihong include:

- Advanced Wireless Power Technologies – Phihong develops high-efficiency inductive and resonant wireless charging solutions for diverse robotic applications.

- Compliance with Global Standards – Wireless power solutions meet UL, IEC, and ISO certifications, ensuring safety in industrial and medical robotics.

- Custom Power Supply Engineering – OEMs receive tailored solutions to meet specific voltage, efficiency, and scalability requirements.

- Global Manufacturing Capabilities – Phihong offers low-volume prototyping and mass-scale production, ensuring reliable supply chain stability.

By partnering with Phihong, robotics OEMs gain access to cutting-edge wireless power solutions, ensuring high-performance charging infrastructure for next-generation robotics applications.